Sold

Noack DPN 760 Blister Packer

Description

Noack DPN 760 blister packing machine with 5 sets of format parts included

Key Information:

- Suitable for packing tablets, capsules, caplets or ampoules

- Maximum foil width 165mm

- Maximum feed length 140mm

- Maximum forming area 150mm x 120mm

- Maximum forming capacity 5 metres per minute

- Recommended maximum forming depth 14mm

- This machine can form to a maximum depth of 24mm with additional/optional tooling (not included)

- Product feed can be manual or automatic

- Maximum reel diameter for forming film 600mm and maximum reel diameter for lidding foil is 250mm

Condition: Good, checked, tested and running

Services available at extra cost:

- Refurbishment/modernisation, including full electrical upgrades (new PLC and HMI)

- Set up to product

- Delivery

- Installation and start up at customer's facility

Specifications

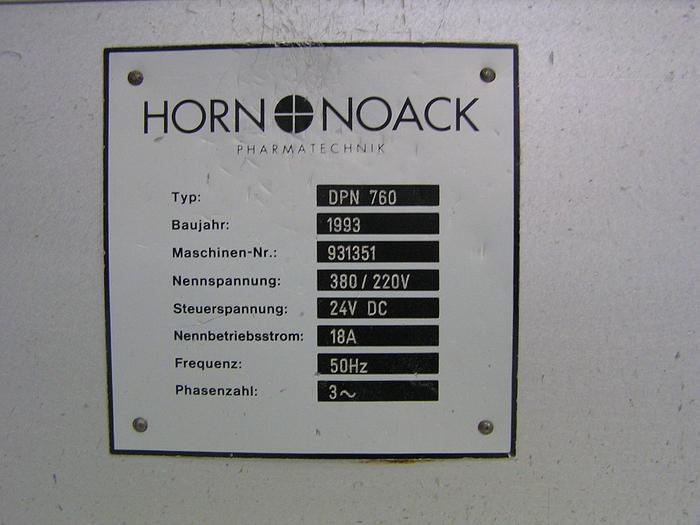

| Manufacturer | Noack |

| Model | DPN 760 |

| Year | 1993 |

| Condition | Used |

| Serial Number | 931351 |

| Stock Number | GP10025 |