2022 Rommelag 360 Blow-Fill-Seal Machine With Cap Welder

Description

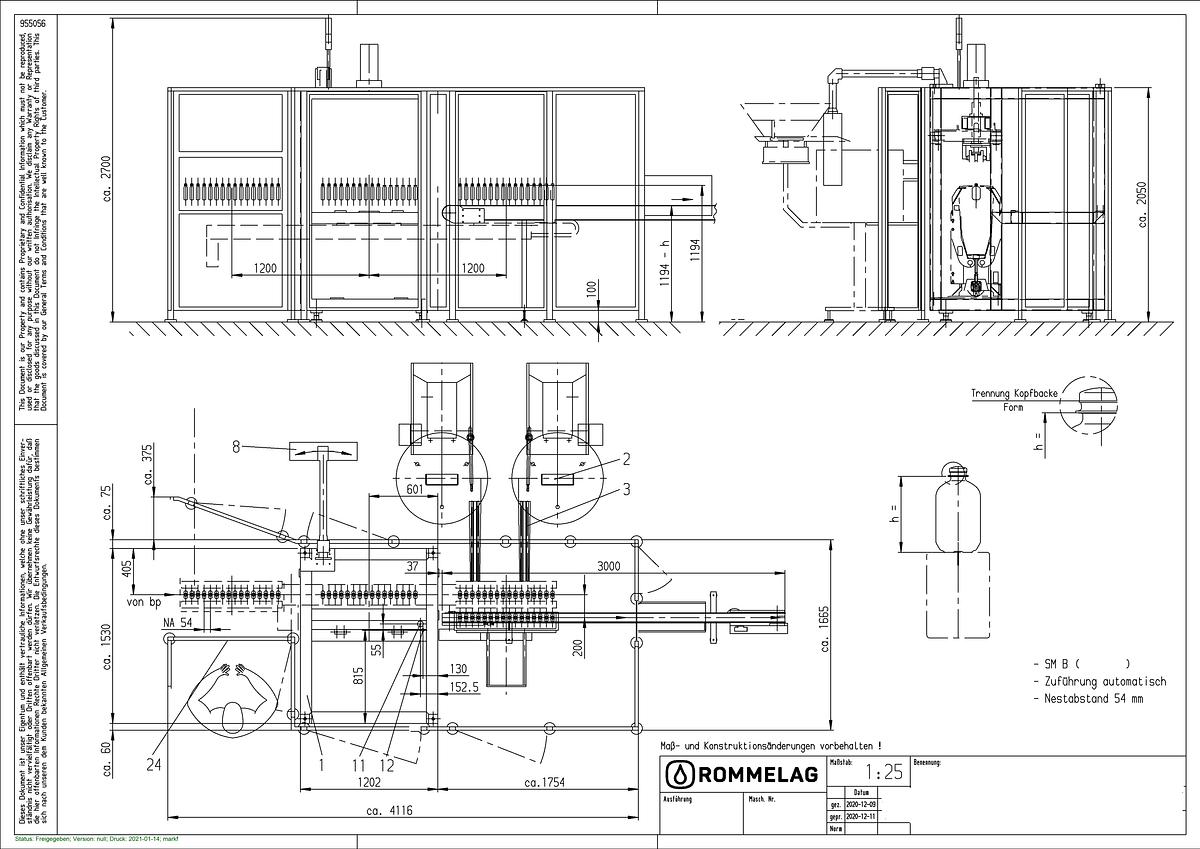

Rommelag Bottelpack Model 360 Blow-Fill-Seal Machine and Cap Welding Machine Model SM 955-A16

Brand New Condition - Never Used

16 cavity machine

Capacity 4000 bottles per hour

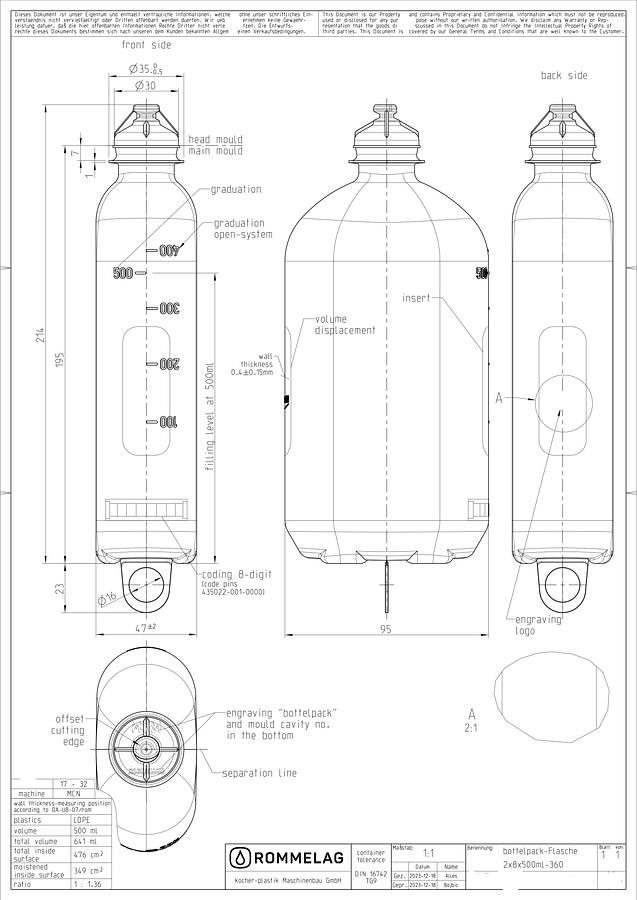

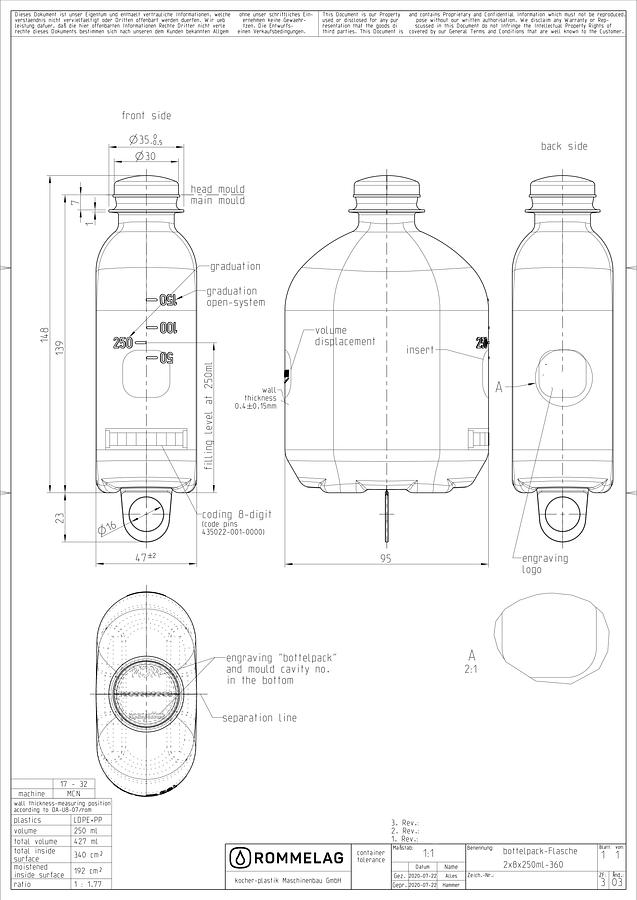

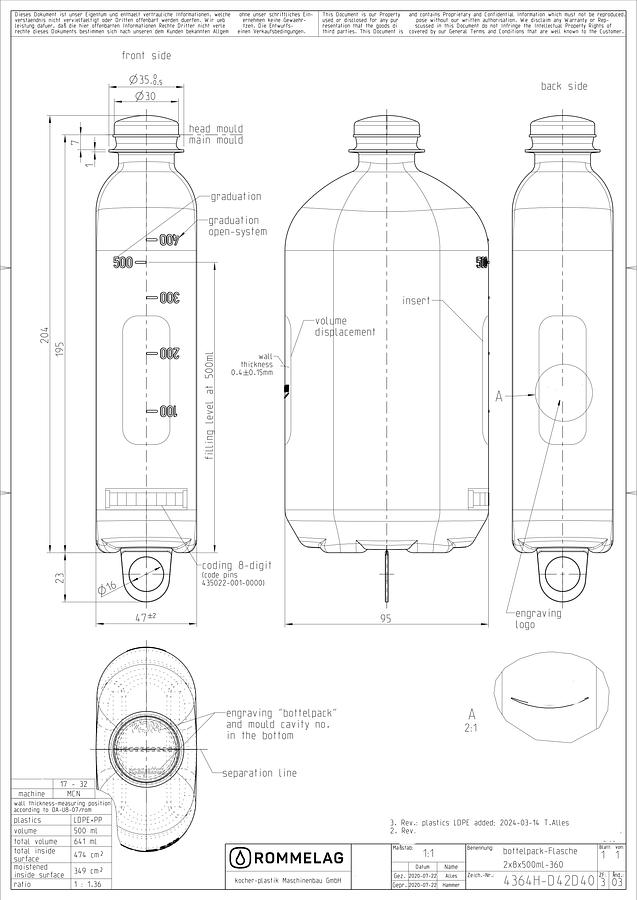

Bottle volume: 250ml and 500ml

Bottle type: PP & PE, Nipple type & Euro head

Plastic Type: LyondellBasell Purell PP RP270G

Plastic Type: LyondellBasell Purell LDPE 3220D

Container drawings attached

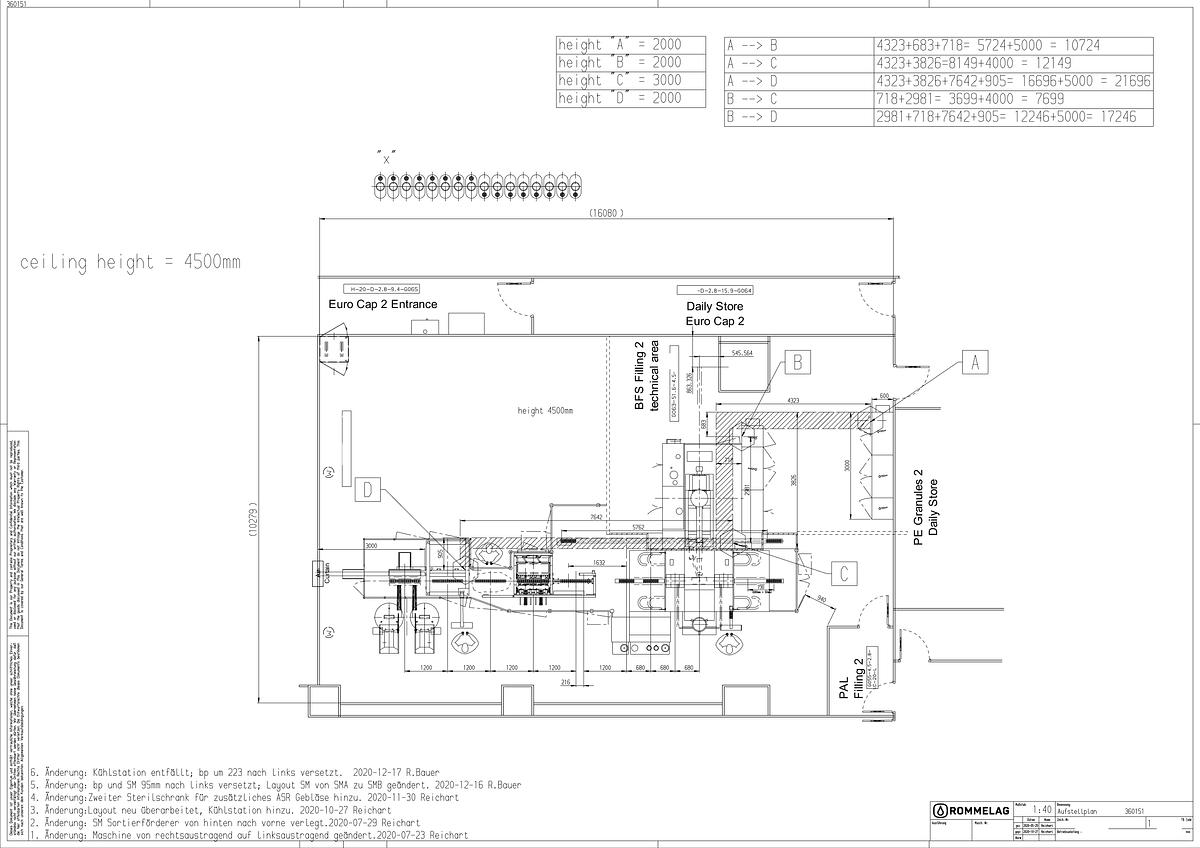

Black and White Separation

"Black and white separation" refers to the strict segregation between classified (sterile, white) and non-classified (non-sterile, black) areas

White Area (Clean/Sterile Zone)

Includes:

- The mold area where the container is formed

- The filling zone where the product is filled into the container

- The sealing zone where the container is hermetically sealed

Black Area (Non-Sterile Zone)

Includes:

- Mechanical and electrical components

- Compressed air systems

- Hydraulic systems

- This zone is not sterile and has lower environmental requirements

Bottle Types: PP and PE, Nipple type and Euro head

Both PP and PE are essential to BFS technology and are selected based on the pharmaceutical product’s needs, sterility requirements, and container specifications

Feature PP (Polypropylene) PE (Polyethylene)

Heat Resistance High Moderate

Rigidity More rigid More flexible

Common Use in BFS IV bottles, large containers Eye drops, unit doses

Sterilization Method Autoclave Gamma, EtO, hot air

Golden package: Validation process

Rommelag’s validation and qualification phases typically follow GMP and ISO standards:

1. Design Qualification (DQ)

Ensures that the BFS machine and tooling (molds) are suitable for the intended product and packaging.

2. Installation Qualification (IQ)

Confirms the BFS machine and utilities are installed according to design and manufacturer specifications.

3. Operational Qualification (OQ)

Tests the machine's performance under typical operating conditions.

Includes forming, filling, and sealing tests.

Initial Golden Packages may be produced here.

4. Performance Qualification (PQ)

Actual production runs using real product.

Multiple batches are produced and tested.

Containers that pass all PQ tests become Golden Packages.

Machines still packed in original wooden case of manufacturer, never unpacked

Machine manuals

Spare parts box

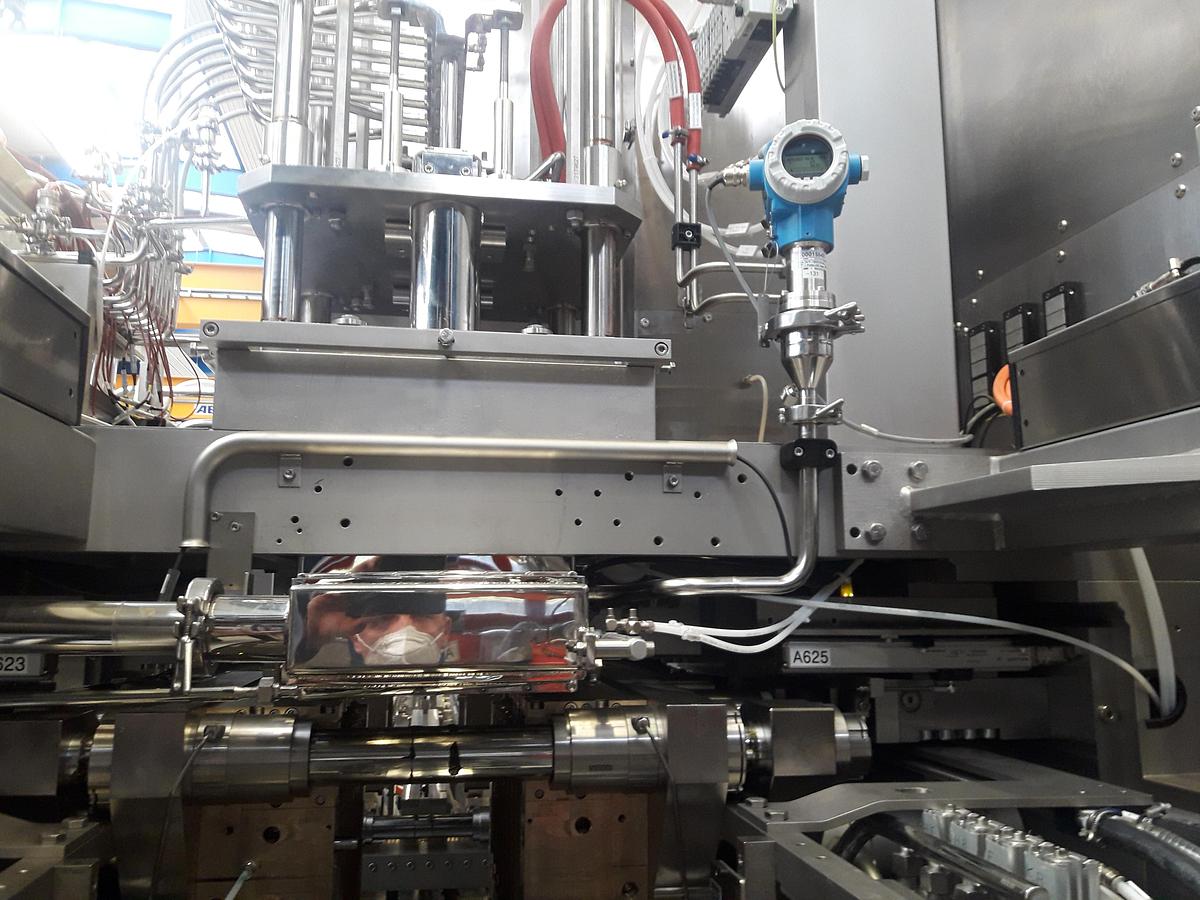

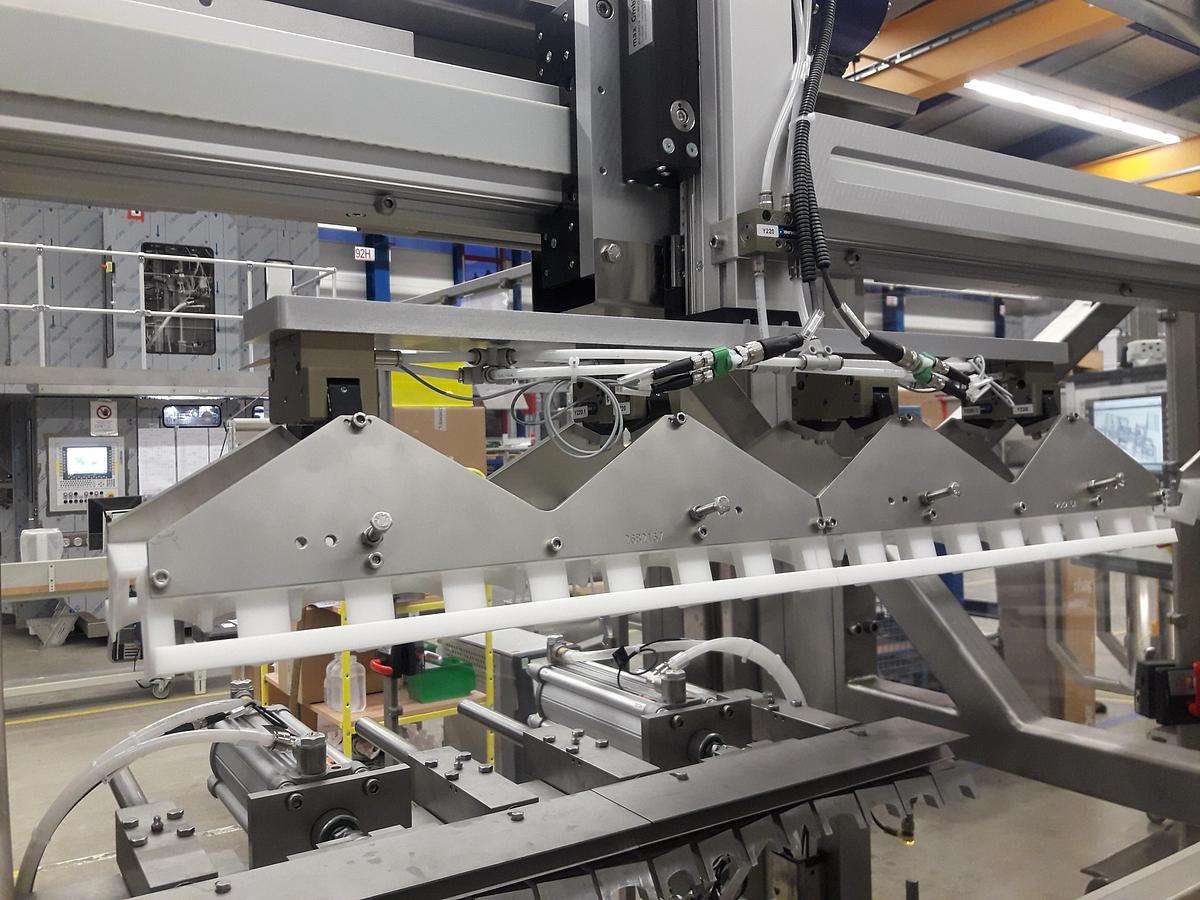

Photos of machine taken at Rommelag Germany

Specifications

| Manufacturer | Rommelag |

| Model | 360 |

| Year | 2022 |

| Condition | Used |

| Stock Number | GP BFS20014 |

| Plastic Type PP | LyondellBasell Purell PP RP270G |

| Plastic Type PE | LyondellBasell Purell LDPE 3220D |