Plumat IV Bag Filling Line

Description

Plumat IV Bag Filling Line

The IV bags are labelled, then filled and plugged and finally vacuum sealed.

The line consists of:

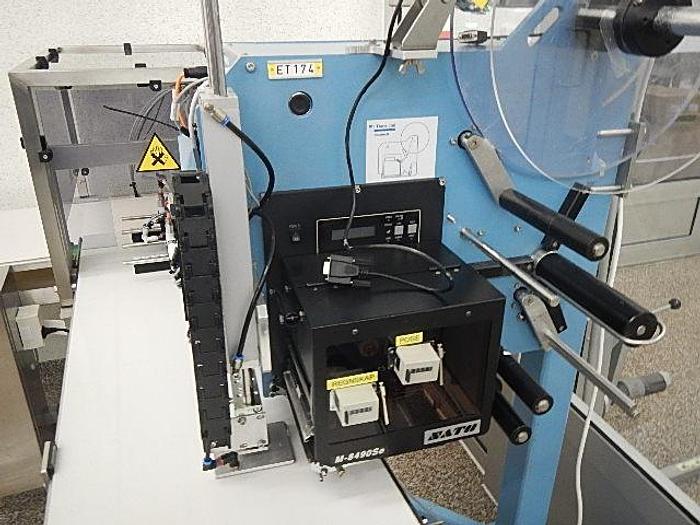

Tiara CML Print & Apply Top Label Applicator

Type IPA 1000 LH, year 2007, serial number 10167

Features:

- Sato printer head (model M-8490SE, year 2007)

- Through conveyor with a conveyor belt width of 420mm

- Software by Label Craft

- Fleximatic fixed speed conveyor with belt width at 520mm used to stack labelled bags (serial number 1275, year 2007)]

- Machine size: 2000mm x 800mm x 800mm high, approx. weight 150kg.

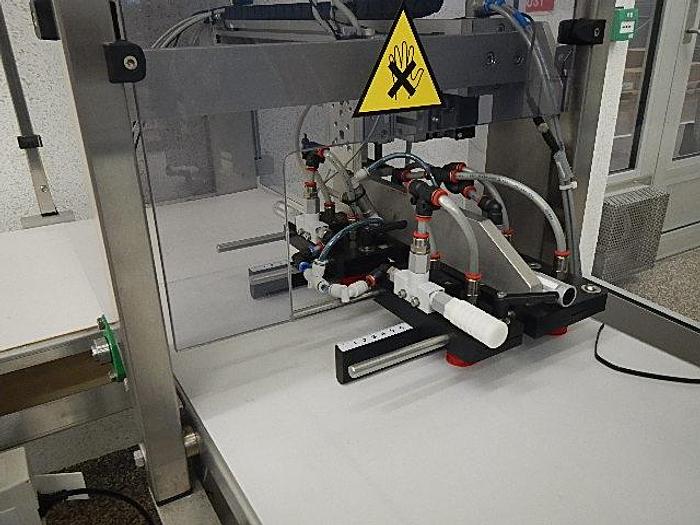

Plumat Plumatex Semi- Automatic Bag Filling and Sealing Unit

Model: BFM 007-4 Year: 2009

Features:

- 4 parallel/filling sealing BFM 007 modules integrated into one frame

- Currently set up for processing infusion and parenteral bags with tube connection

- Suitable for the following packing materials: PP/PE/PVC/EVA/EVOH (lastly used on PVC)

- Apart from infusion bags and parenteral products it is widely used for antibiotics, cytostatics, flushing solutions and dialysis systems

- All product contact parts are made from AISI 316L

The bags are manually fed into the machine. The operator continuously loads the four modules in succession by putting the tubes of the bags into the tube reception devices of each module, thereby a contact switch is actuated signalising that the bag has been loaded. The fill tube is centred automatically, and the filling nozzle moves down to enter the fill tube and fill empty bag. The operator starts the automatic filling and sealing process with two hands by pressing the buttons. This machine is suitable for PVC bags with twin tube port and non-PVC bags with one tube port.

It can be used in 3 sealing methods:

- Closure “A”: injection stopper – mode: automatic stopper feeding

- Closure “B”: blind stopper PG 100.30; mode: automatic stopper feeding

- Closure “C”: twist off stopper – mode: manual stopper feeding.

Capacity (with 2 operators):

- 3200 bottles per hour (100ml)

- 2800 bottles per hour (250ml)

- 2600 bottles per hour (500ml)

- 1700 bottles per hour (1000ml)

- 800 bottles per hour (2000ml)

Fill accuracy:

- +/- 1.5% (100ml)

- +/- 1.0% (250ml)

- +/- 0.7% (500ml)

- +/- 0.5% (1000ml)

- +/- 0.3% (2000ml)

- +/- 0.2% (5000ml)

Dosage system: Massflow filling system in connection with a pneumatic fill valve, in-line sterilizable (CIP/SIP) up to 125 Celsius

Product infeed connection: tri-clamp DN40

Fill range: 50ml up to 5,000ml

Conveyor belt width: 480mm

Operating voltage: 230 V

Frequency: 50 Hz

Power consumption: 0.8 kW

Compressed air: approx. 6 Bar

Compressed Air Consumption: approx. 20 Nl/m

Clean Air consumption: 400l/h

Complete with manuals, technical drawings and Operator Manuals (including CD copy) in English and Norwegian

Machine size: 2800mm x 1500mm x 2000mm high, approx. weight 895kg.

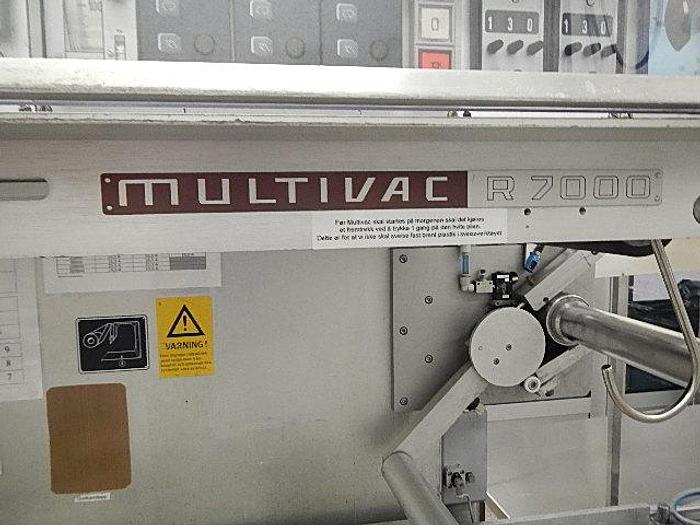

Multivac R-7000 Thermoforming Machine

Model R7000 Year 1984

High performance horizontal, rollstock thermoform, fill, seal, deep blister packing machine suitable for use in food industry, medical devices and pharmaceuticals, industrial and consumer goods.

Maximum 30 cycles per minute depending on package size, depth of draw, film used and capacity of vacuum pump.

Multivac 7000 produces packages from two separate rolls of film: the bottom web is thermoformable material and is used to make the pockets which hold the product, the top web, which is often printed, forms the lid.

The bottom web is fed into the grippers of the transport chain via a brake shaft. By means of a drive motor the film is moved forward at regular intervals, first going through the forming station, where pockets are produced by heat and air pressure.

Web widths:

- Minimum 10.24 in. (260 mm), maximum 24.41 in. (620 mm)

- Standard widths: variable from 13.39 in. to 18.11 in. (340 mm to 460 mm), 15.75 in. to 20.47 in. (400 mm to 520 mm), (19.69 in. to 24.41 in. (500 mm to 620 mm).

Packaging material: all thermoformable or heat sealable films

Film roll diameter:

- Top web, maximum 15.75 in. (400 mm)

- Bottom web, maximum 19.69 in (500 mm)

- Roll core diameter 3 in. (76 mm) or 5.98 in. (152 mm)

- Cut-off 4.72 in. to 31.50 in. (120 mm to 800 mm), standard up to 12.60 in. (320 mm)

Depth of Draw/Product Height: Up to 6.30 in. (160 mm), standard up to 3.94 in (100 mm)

Dies: Each package size or type requires an appropriate set of dies. A die change can be made in about 15 minutes. The die charts comprehend about 1000 different standard dies.

Loading Area: Approximately 29.53 in. to 157.48 in. (750 mm to 4,000 mm).

Also available in knee-free style.

Drive and Control: Film advance via brake motor and change gears.

All other functions electronically and pneumatically controlled

Complete with manuals and documentation in English

Specifications

| Manufacturer | Plumat |

| Model | BFM 007/4 |

| Year | 2009 |

| Condition | Used |

| Stock Number | GP10018 |

| Model | BFM 007-4 Year |

| Fill range | 50ml up to 5,000ml |

| Operating voltage | 230 V |

| Frequency | 50 Hz |