In the realm of pharmaceutical and packaging industries, innovation plays a pivotal role in ensuring the safety and efficiency of products. One such groundbreaking technology that has revolutionized the packaging process is the Blow-Fill-Seal (BFS) machine. In this comprehensive guide, we'll delve into the intricacies of BFS machines, exploring their functionality, applications, and the myriad benefits they bring to the table.

What is a Blow-Fill-Seal (BFS) Machine?

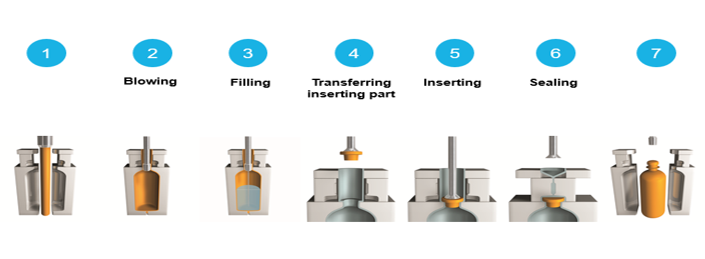

Blow-Fill-Seal (BFS) is a state-of-the-art technology used for the aseptic packaging of pharmaceuticals, biotech products, and even food and cosmetic items. This advanced packaging method integrates three key processes – blowing, filling, and sealing – into a single, continuous operation within a sterile, closed system.

The BFS Process Unveiled:

1. **Blowing:**

- The process begins with the creation of a plastic container through the blow molding technique.

- This ensures a seamless, uniform container with precise dimensions, tailored to the specific needs of the product.

2. **Filling:**

- The container is then filled with the desired product, such as liquid pharmaceuticals, ensuring a high degree of accuracy and precision.

- This step is carried out under strict aseptic conditions, minimizing the risk of contamination.

3. **Sealing:**

- The final step involves sealing the container, protecting its contents from external contaminants and ensuring product integrity.

Blow-Fill-Seal (BFS) machines represent a cutting-edge technology that has transformed the packaging landscape, particularly in the pharmaceutical industry. The seamless integration of blowing, filling, and sealing processes in a sterile environment ensures the delivery of safe, high-quality products to consumers. As industries continue to embrace innovation, BFS technology stands out as a beacon of efficiency and reliability in the packaging world. Embrace the future of packaging with BFS technology – the epitome of precision, sterility, and speed.

*(SEO Keywords: Blow-Fill-Seal machine, BFS technology, aseptic packaging, pharmaceutical packaging, biotech products, packaging innovation, continuous production, sterile packaging, packaging efficiency, cost-effective packaging.)*